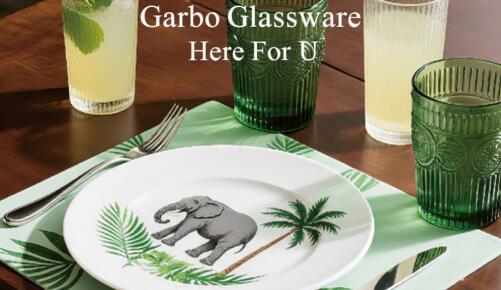

Beyond transparency: Why do top brands choose our solid colored glassware for their marketing

Pulished on Sep. 30, 2025Is your glass product line lacking competitiveness due to a single design? Are you looking for a glass supplier who can enhance your brand and guarantee a stable supply of large quantities?

Garbo is an expert in the research and development and production of colored glass cups, and can provide customers with a full range of solutions from color customization, process innovation, to mass production.

The craftsmanship and advantages of solid colored glass

The essential difference between "pigmented glass" and other coloring methods, such as "spray painting, film", is that its core advantages are long-lasting color, environmental protection, non-toxicity, and high-quality texture.

Core Technology Highlights for solid colored glassware:

Uniformity: How to ensure high color consistency between batches during mass production?

We strictly follow the formula we developed for production. This formula will be tested at least 5 times before production to ensure color uniformity.

Stability: The integration of the pigment into the glass, ensuring lead- and cadmium-free leaching (compliant with FDA, LFGB, and other international standards), dishwasher resistance, and acid and alkali corrosion resistance.

Color Range: normally, we have 4 regular solid color glassware, grey, blue, green, and pink. Apart from these 4 colors, the red, amber, Tiffany blue, or other custom colors are acceptable.

Client Background and Challenges.

Scenario: A global home furnishings giant wanted to launch a set of stylish, cost-effective, and environmentally friendly glassware for its new seasonal kitchen collection.

Task/Challenge: The client's requirements were very specific and demanding:

Color Accuracy: The product needed to match the seasonally popular red color palette and maintain high batch-to-batch color consistency.

Stringent Environmental Standards: The product had to pass EU LFGB and US FDA standards, and provide authoritative test reports.

Tight Delivery Time: From sample approval to delivery of 100,000 units, the timeframe was just 55 days.

Cost Control: Competitive pricing was required while maintaining quality.

Our Solution:

Our sample department's colorists provided five fine-tuned samples within seven working days, ensuring minimal deviation from the Pantone color chart. This provided the client with a variety of options and allowed them to make a quick decision.

Exclusive Eco-Friendly Formula: We used our proprietary lead- and cadmium-free pigment formulation and provided a comprehensive migration test report from SGS with the samples, fully complying with the client's required international standards.

Production Line Optimization: For this project, an automated production line was specially developed to optimize the melting and cooling processes, reducing the production cycle by 15%.

Value Engineering Analysis: Our engineers recommended a specific mold design and raw material ratio, which, while ensuring strength and aesthetics, saved the customer approximately 7% in unit cost.

Achievements and Value:

Successful Delivery: All products were delivered three days ahead of schedule, with an unpacking defect rate of less than 0.3%, far below the industry standard of 1.5%.

Market Success: This series of ice cream cups became a hit of the season upon launch, achieving a 200% repurchase rate for the first batch of orders in the target market.

Long-Term Partnership: Based on this successful partnership, the brand has designated us as a core glassware supplier in the Asia-Pacific region and has entered into a deeper product development collaboration.

Production Base Overview:

Jiabao International has 3 glassware factories (1 factory for machine pressing + 1 factory for machine blowing + 1 factory for manual).Thus total factory area is over 100,000 square meters

There are 6 furnaces and 20 production lines (including 10 machine-pressed glass production lines, 3 machine-blown glass production lines, 3 post-processing production lines, 2 white jade glass production lines, and 2 fully automatic row machine production lines)

Core Manufacturing Equipment:

Equipped with a fully electric furnace imported from Germany, our temperature control accuracy reaches ±1°C, ensuring the high purity and color stability of the molten glass.

Our automated line machines are sourced from the United States and Italy, with a daily production capacity of 800,000 pcs, ensuring on-time delivery of large orders.

The 50-meter-long precision annealing tunnel kiln uses computer-controlled temperature to effectively eliminate stress within the glass, making the product more resistant to temperature differences and less prone to cracking.

We also have professional cutting, polishing, printing and sandblasting workshops to meet your various in-depth processing needs for glass cups.

We have established long-term cooperation with world-renowned chemical companies and conduct strict testing on each batch of quartz sand and pigment masterbatch entering the warehouse to ensure product quality from the source.

Strict QC check.

At each key point of production (such as drop, molding, annealing), there is a quality inspection station, using automatic inspection machines and manual double inspection to eliminate products with defects such as bubbles, stones, deformation, etc.

All finished products are 100% water pressure tested (for sealing products) and visually inspected. We have an independent quality inspection center equipped with professional equipment such as impact testers and thickness gauges to ensure that the products meet the highest standards.

R&D and Innovation: Future-oriented Capabilities

We have a R&D department comprised of X materials engineers and designers. We're not only dedicated to developing new formulas, but we can also provide forward-thinking product design recommendations based on your market trends.

Customization Capabilities: "We understand the importance of customization. We offer flexible prototyping services, with a typical turnaround time of 7-10 business days for new colors/designs.

We can also offer small-batch trial runs (low MOQs) to help you mitigate market testing risks.

R&D Team: We have developed over 3,000 tableware designs. Our 20+ design team, led by a graduate of Tsinghua University's Academy of Fine Arts, strives to create "the world's highest-quality tableware."

We are not only dedicated to developing new products, but also provide forward-thinking product design recommendations based on market trends.

Customization Capabilities: We understand the importance of customization. We offer flexible proofing services, with a typical turnaround time of 7-10 business days for new colors/designs.

Contact the manufacturer's sales team today for a personalized quote and samples!