What standards should a good glass meet?

Pulished on Nov. 14, 2019To take a normal glass cup out of the cold water, then pour the boiling hot water into the glass, it is likely to be broken. However, the same way for the high borosilicate glass cup and it will be intact. Because high borosilicate glass is characterized by high temperature resistance compared with ordinary glass, For its high temperature resistance , it is usually used in a variety of shapes, which used in chemical, aerospace, military, family, hospital and other fields. Only passed qualified borosilicate glass can withstand the instantaneous temperature difference of 150 °C among them, and it is safe to pour cold drinks and hot drinks into it. Therefore, what standards should a good glass meet for inspector?

Pure quality in the case of non-direct light, visually measure bubbles, cracks, and particles at a distance of about 30 cm, supplemented with a 10x graduated magnifying glass if necessary.

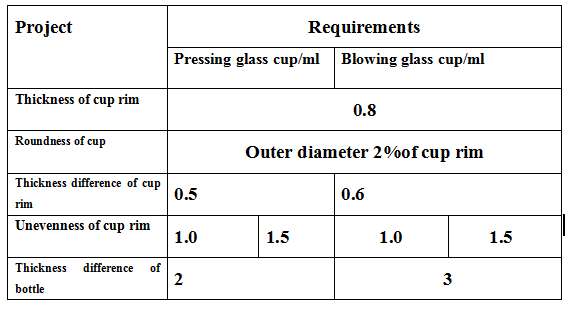

Thickness and uniform thickness can be measured with a thickness gauge of 0.02mm. The thickness of the cup can be measured at 3mm below the mouth of the cup; the thickness difference of the mouth is measured at the same level within 10mm below the cup, and the minimum thickness is minimized. The specific criteria are as follows:

Thicken the bottom of the cup to the desired thickness by hand blowing is not only difficult but also costly, which is also easy to cause uneven thickness of the bottom of the cup. How to produce manual borosilicate glass, which naturally achieves the above criteria?

The first step of the Handmade glass production is design

In order to design a suitable and beautiful glass for the tea, the designers of the collection have studied courses related to the tea artist. After completing the first draft of the design, the team members need to discuss the improvement points, repeat proofing and try new products.

The second step of the Handmade glass production is making a knife

The knife maker makes a good knife that matches the new product turning curvature according to the design draft, so that the mold is not offset when it is built.

The third step of the Handmade glass production is making mold

The final shape of the product is determined by the mold. No matter how small the spots or scratches on the mold, it will directly affect the beauty of the glass. Therefore,the mold making process especially to test the patience and meticulousness of the craftsman.

However, Garbo glassware can meet above requirements that producing better glassware with high quality.We insist on putting the function and quality in the first place. We have designed and developed a series of high quality, practical and unique designed products to express the style and quality of life for people.