Why Global Distributors Choose Our Tempered Glass Cups

Pulished on Jul. 05, 2025Tired of customer complaints about broken glassware during shipping? Our tempered cups withstand 3 times more impact than standard glass.

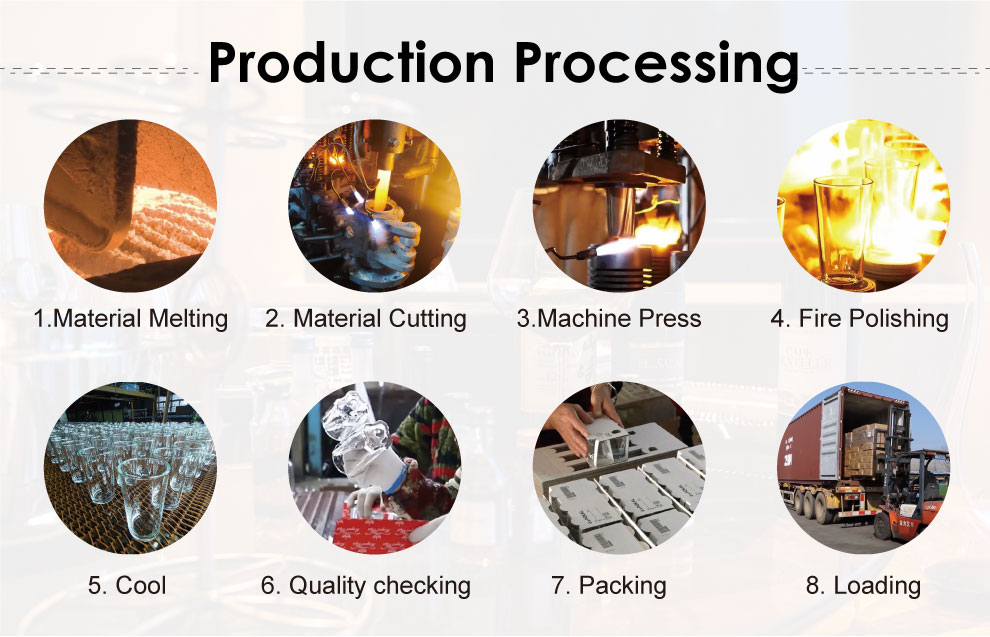

Our soda-lime tempered glass undergoes precision engineering:

Chemical Composition: 72% SiO₂ + 14% Na₂O + 10% CaO + trace MgO/Al₂O₃ for optimal balance of clarity and strength.

BPA-free drinking glasses wholesale are of premium quality, which can reach food grade standards such as EU, LFGB, ROHS, REACH, FDA, DGRRCF and other standards.

Thermal Tempering:

Heated to 600°C for uniform stress distribution.

Rapid quenching with high-pressure air jets (25 m/s) to achieve surface compression >10,000 psi.

Soda-lime glass with 12% boron oxide for thermal shock resistance,

Our tempered glass cups can withstand the thermal shock of 120 ℃,

Heat-Resistant: Microwave safe, safe for boiling water, best choice for drinking coffee and tea.

Cold Resistant: Freezer safe, withstands cold temperature -20 ℃

Supply chain advantage.

Why Transparency Matters to Buyers?

Global procurement teams prioritize suppliers with clear supply chains, reducing risks of delays, quality issues, or compliance violations.

Our vertically integrated manufacturing ensures full traceability from raw materials to finished goods.

Live Production Timeline for tempered glass cups bulk orders. (Case Example: Order #2025-EU0205)

Day 1-7: Raw Material Sourcing

Glass sand from ISO-certified China suppliers (SiO₂ purity >99.5%)

Real-time tracking: Batch #XG-2025-02, Strict quality checking for the incoming raw material by our QC team.Day 7-14: Tempering & Molding

Automated annealing at 680°C, 100% optical inspection: Rejects 0.7% of units for micro-bubbles (vs. industry avg. 2.1%)

Days 14-20: Customization

Digital printing audit trail: Pantone 19-4052 TCX "Classic Blue" approved within 4 hours.

Preproduction samples are available to confirm all the details for the tempered glass cup.

Day 20-27: Logistics Prep

Pre-shipment video call: Buyer verifies carton labeling & container loading

An in-house QC checking report or a third-party QC report will be sent to clients for approval.

The QR codes on cartons, color boxes, and stickers can be tracked.

Customization Services

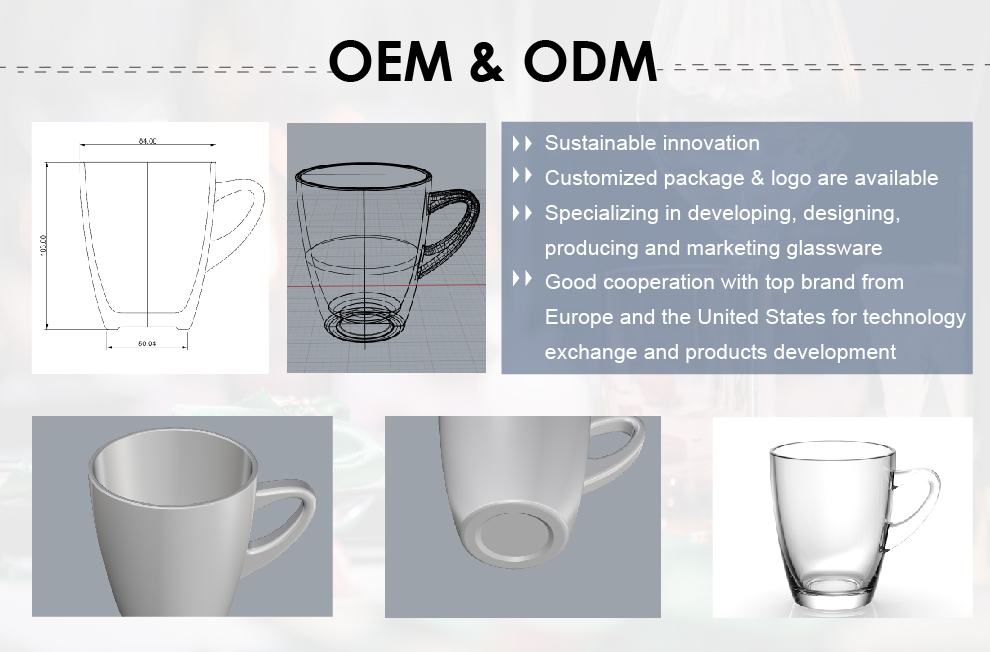

As an OEM glassware supplier in China, we can transform your vision into market-ready glassware cups with 3-tier customization.

Level 1: Logo/Branding

Colorful Printing/Decal: The customized logo or pattern can be added to the glass cup's body or the bottom of the glass cups.

Mould logo(as engraved pattern): if you need the glass cups to be safe for use in the dishwasher, the engraved logo on the glass cups is suggested.

Level 2: Structural Modifications

Mold adjustments for:

✓ Ergonomic grips (e.g., ergonomically friendly grip beer tumblers with a wide handle)

✓ Stackable function cups or jugs (30% more efficient than standard cups)

3D Prototyping: Receive functional samples within 48 hours. This can help save time and energy to confirm new design glass cup details, including size, shape, and engraved pattern.

Level 3: Full OEM Development

Co-engineering for patented designs, share the mould fee.

Handmade mould for preproduction sample to confirm most of the details before manufacture(in this way, handmade mould glass cup samples look more similar to the actual production goods.

The designer and the client can adjust the details based on the handmade mold samples. Customers can directly feel the weight/grip of the sample (digital models cannot replace this)

Handmade sample lead time: 7-10 days after details are confirmed. It is with low-cost Efficiency and high time efficiency.

The machine-made mould.It takes around 15~25 days to open new mould based on the specified data.

Packaging Customization

Option Cost Add-On MOQ Best For

Kraft Paper Sleeves for Eco-conscious brands

PVC-Free Blister Packs for Retail Shelf Appeal

Foam-Insert Gift Boxes for Luxury Hospitality

Mailbox with polyfoam for online shops,

A Dabai hotel chain reduced in-room breakage by 62% using our foam-lined crates (custom die-cut to fit 24 cups).