Garbo - High-end Crystal Glassware OEM/ODM: Your Right Customization and Health Choice

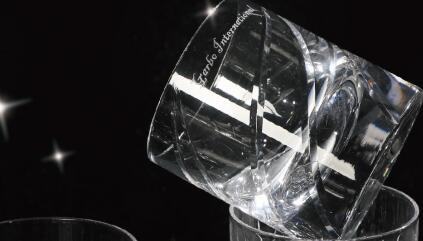

Pulished on Oct. 13, 2025Would you like sparkling Whisky thick-bottomed crystal cup? There is no doubt that no one would not like this treasure which can compare with shining jewelry. It is worthy to take it as presents or keep it for daily used.

Garbo, the high-end crystal cups manufacturer, is the OEM and ODM in glassware industry for more than 30 years. For many years, Garbo is praised with the artistic level and luxurious taste of the products for its high quality glassware.

How Can Garbo Keep the Core Competitiveness for Decades?

The reason is that Garbo equips with the innovative technology, exquisite polishing skills and application of high refractive index crystal glass.

1. Innovative Technology for Production

For producing these crystal cups, Garbo has put into more than USD $20,000 each year in advancing machines for detecting the innovating the glassware technology like 3D printer, laser drilling machine. With these machines, it makes the glass cups design and production more complex and specific. This operation helps Garbo to achieve to high degree in fineness and personal designs that traditional crafts are unable to be.

2. Craftsmanship and Innovation

Exquisite polishing technology is the core of the value of crystal glass. Since 1998, craftsmen have been cultivated the skills like hand blown, cutting and engraving etc. Based on this, Garbo also combines these skills with automated polishing machine to make the surface roughness of the glassware beyond micron level(Ra < 0.1μm). This step not only ensures the ultimate gloss but also the smooth feel when touching the shining cups.

3. Quality Control

Strict quality control of products go through all the process in mass production. In addition, all the procedures are monitored to make sure quality. At the final stage, the finished products will be checked strictly according to the standard of DIN EN 10204 etc. All of these efforts are made to achieve customers' expectation.

With these core competitiveness, crystal glass cups of Garbo owns the high refractive index, it also enhances its performance under different light conditions. In this case, Garbo cups attract most of attention from the high-end catering, wedding and festival gifts markets.

What Are Differences Between Garbo's Crystal Cups from Others?

Before launching the products, 5 different departments of Garbo fully has considered the health, environment protection and unique design to meet customers' request for high quality life.

1. Thickened Cup Bottom Design

This design is considered for the thermal insulation performance, durability, anti-slip, feeling and stability. Thickened cup bottom design can be effectively slow down the change of beverage temperature. According to the principles of thermodynamics, increasing the bottom thickness increases heat capacity can extend the time the drink and remain at the desired temperature. For example, the bottom thickness of some high-end whiskey glasses can be as thick as 1.5-2.5 cm, which not only increases the stability of the glass but also enhances the drinking experience.

The unique thick bottom design improves the comfort and stability of holding, especially suitable for high-end drinks such as whiskey and cocktails, highlighting the user's taste.

The thick base significantly enhances the cup's impact resistance, reducing the risk of breakage. Furthermore, its increased weight and friction enhance its anti-slip properties, reducing the likelihood of accidental tipping. This is particularly important in high-frequency usage scenarios like hotels and bars, reducing product breakage by 10%-15%.

2. Healthy and Environmentally Friendly Materials

Garbo strictly select lead-free crystal materials that meet international food contact standards. The crystal glass meets the US FDA (Food and Drug Administration) and European food safety standards. This means that under normal use conditions, the product will not migrate harmful substances into food, ensuring that consumers can use it with peace of mind.

During the production process, environmentally friendly processes are actively adopted to reduce energy consumption and waste emissions. By 2025, green manufacturing subsidies are expected to drive related investment growth by 30%, prompting companies to adopt more environmentally friendly production methods. This not only conforms to the global trend of sustainable development, but also enhances the brand's social responsibility image.

What Are the Service Highlights of Garbo Glassware?

By providing the personalized customization service and build an efficient supply chain, Garbo comprehensively assists customers' brand upgrading and meets diverse market demands.

1. Personalized Customization Service

Garbo is able to offer comprehensive OEM/ODM services, from concept design and mold development to mass production. For example, through 3D modeling and rapid prototyping, we can complete initial design verification within 7-14 days, significantly shortening product development cycles. This allows hotels and restaurants to customize glasses with their own logos or unique designs, enhancing their brand image.

Additionally, offering a variety of customization options for different customer groups is also achievable, including cup shape, capacity, engraving, pattern carving, and packaging design. For example, for the high-end gift market, limited edition or commemorative customized products can be provided to meet customers' demands for uniqueness and exclusivity. Statistics show that personalized customization services increase customer satisfaction by over 20%.

2. Bulk Order Fast Delivery and Global Wholesale

Equipping the advanced automated products lines and effective production manage system, Garbo has the ability to quickly respond to bulk order demands. For example, a modern glass production line can produce tens of thousands of glasses per day, enough to meet the purchasing needs of large hotel groups or chain restaurant companies. Garbo has 7 different products lines for mass production.

By establishing long-term partnerships with global logistics partners, Garbo can achieve rapid global logistics and delivery. For example, by optimizing warehousing and transportation networks, the average delivery cycle for international orders can be shortened by 15%-20%, ensuring timely delivery of products to customers.

As the direct supplier, Garbo effectively controls production costs and offers more competitive prices. Furthermore, strict production standards and quality management systems ensure high consistency in product quality across all batches, providing a solid guarantee for global wholesalers and brand customers. For example, through lean production management, unit production costs can be reduced by 5%-8%, maintaining a price advantage in the market.

Garbo is such an experienced and professional manufacturer in glassware industry. Place an order at Garbo, you can rest assured.